uni is a global leader in modular plastic belting and chain solutions, delivering cutting-edge conveying technologies for industries such as food processing, packaging, automotive, and material handling. Known for their durability, flexibility, and hygienic design, uni’s modular belts and chains are engineered to optimize efficiency and reduce downtime in even the most demanding industrial environments. Their products are designed for easy maintenance, superior strength, and excellent resistance to wear, chemicals, and extreme temperatures. uni’s innovative solutions meet the highest industry standards, ensuring safe, reliable, and efficient operations across a wide range of applications. Whether for complex conveyor systems or simple material transport, uni offers customizable solutions tailored to specific operational needs. With a strong commitment to quality, technical support, and continuous innovation, uni has earned the trust of industries worldwide. Their modular belting solutions help businesses improve productivity, minimize maintenance, and achieve consistent, high-performance results.

uni

A leading provider of modular plastic belts and chains, uni ensures seamless and hygienic conveying for industries including food processing, packaging, and automation. Built for reliability, engineered for efficiency.

Overview

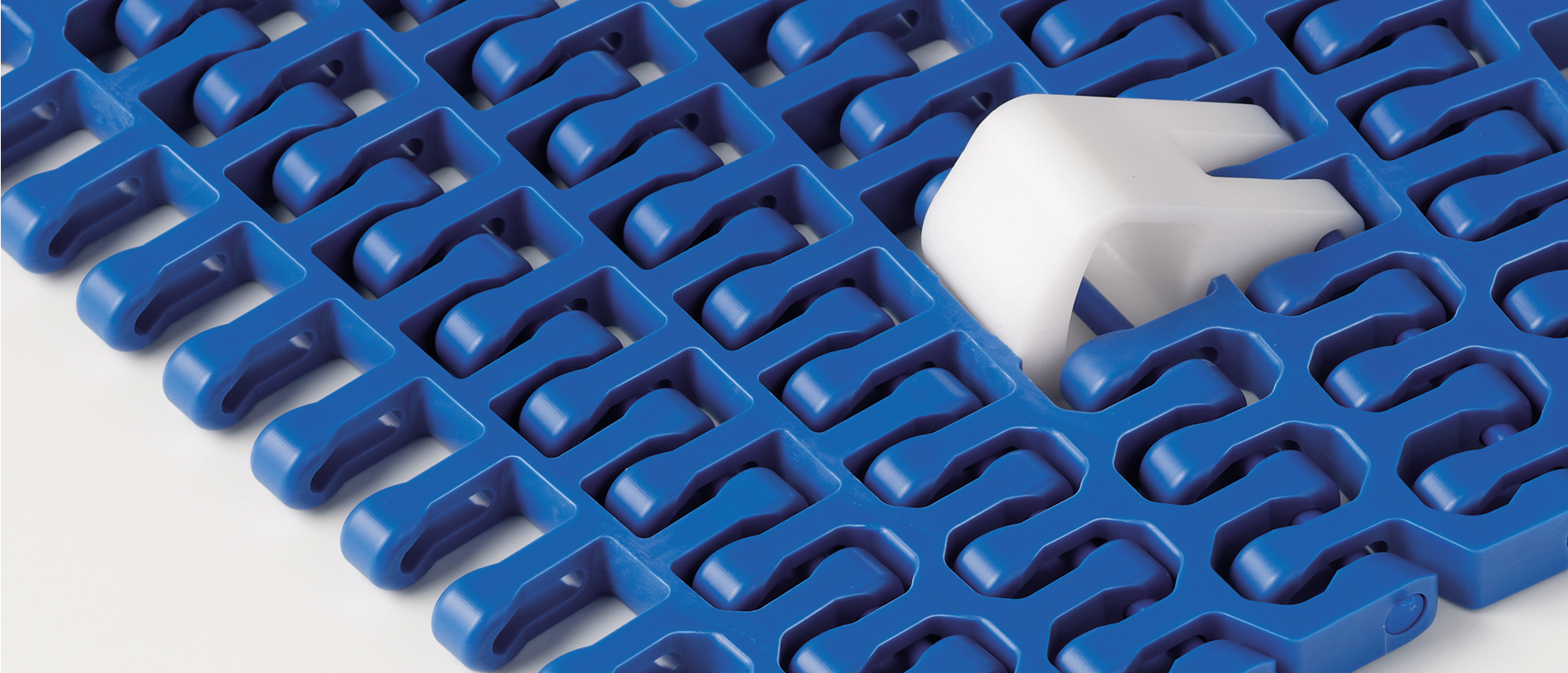

Engineered for Seamless Conveying

Modular plastic belts and chains designed for precision, hygiene, and durability. uni keeps your operations running efficiently from start to finish.

Built to Withstand Demanding Environments

Food processing, packaging, and automation industries rely on uni belts for their strength, reliability, and resistance to wear and tear.

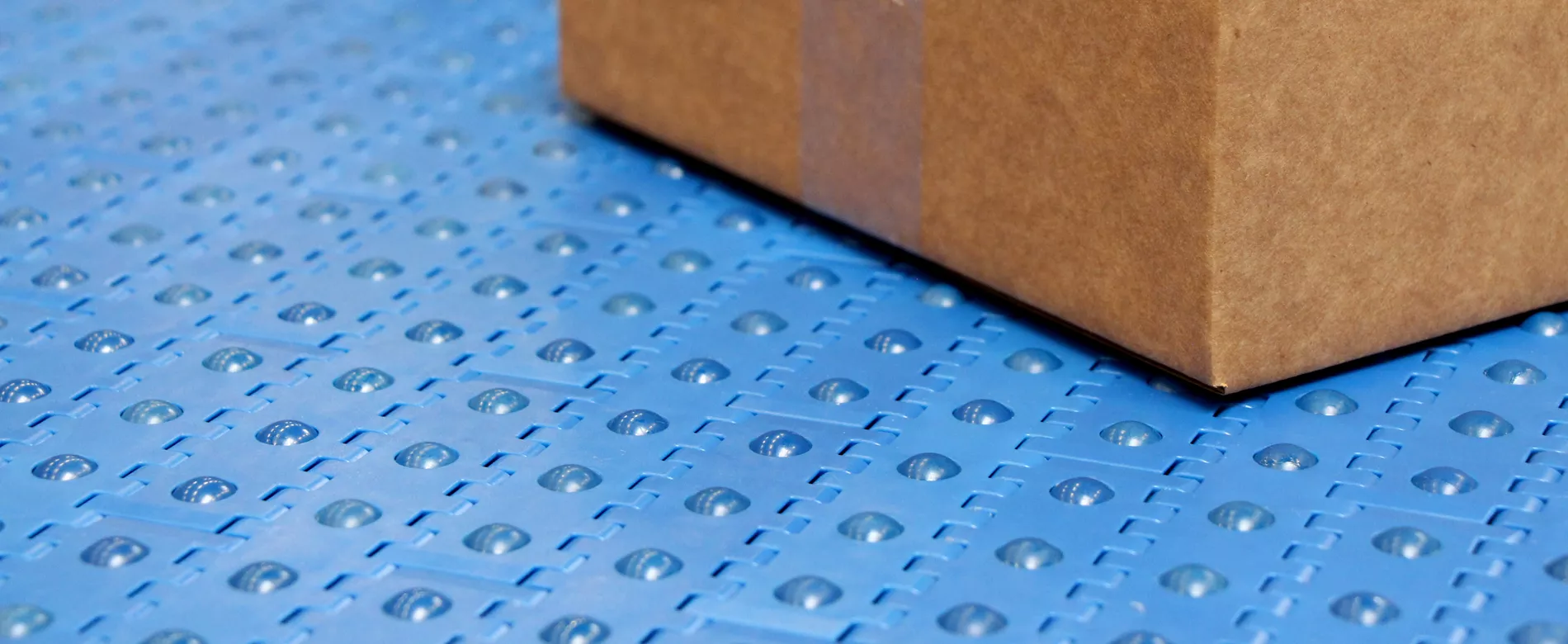

Optimized for Clean, Safe Operations

Hygienic design meets rigorous industry standards. uni belts simplify cleaning and maintenance, reducing downtime and maximizing productivity.

Custom Solutions for Every Application

Modular flexibility ensures uni belts fit your exact specifications, offering tailored solutions that enhance operational efficiency.

Trusted Worldwide for Performance

Industries across the globe choose uni for modular belting solutions that deliver consistent, reliable performance in the toughest conditions.